看了混炼造粒一体机技术参数-3L的用户又看了

留言询价

留言询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

型 号 Model | P-H-3L-DCSS-H | |

密炼腔容积 Mixing Cylinder Cubage( L) | 3L | |

挤出螺杆直径 Diameter of Extrusion Screws( φ)(mm) | Φ45 | |

混炼电机功率 Mixing Motor Power ( KW) | 7.5KW | |

混炼变频调速功率 Mixing Inverter Control Power ( KW) | 7.5KW | |

挤出电机功率 Extrusion Motor Power ( KW) | 2.2KW | |

挤出变频调速功率 Extrusion Inverter Control Power ( KW) | 2.2KW | |

切粒电机功率 Dicing Motor Power ( KW) | 0.75KW | |

切粒变频调速功率 Dicing Inverter Control Power ( KW) | 0.75KW | |

加热功率 Heating Power ( KW) | 5KW | |

温控区数 Temperature Control Interval No. | 四区 | |

电器控制 Electric Control | 智能温控表 Intelligent Temperature-controlled Table + PLC编程+触摸屏控制 Touch Screen Control | |

**切粒转速 Max Rotating Speed of Dicing | 180r/min | |

出料小孔径 Small bore Discharging | Φ3.5 | |

切刀吹气冷却 Slicer Cooling | 电磁气阀自动控制 Automatically Control by Solenoid Valve | |

全机重量 Total Weight | 约1.1吨 about 1.1 Ton | |

安装尺寸(米) Size of Installation( M) (长X宽X高) ( L x W x H) | 2×1.1 ×2.3 | |

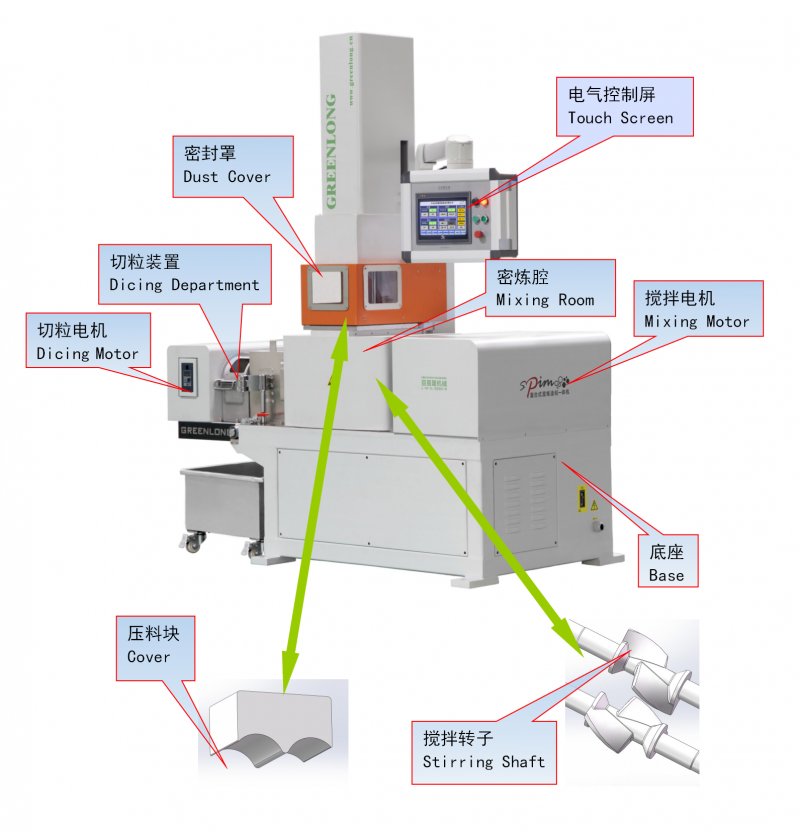

主要零部件明细

Main Part List

序号No. | 名称Name | 规格型号Model | 单位Unit | 数量Qua | 制造商Maker |

1 | 密炼腔Mixing Room | 3L | 件Pics | 1 | 亘易隆GREENLONG |

2 | 搅拌转子Mixing Shaft | 3L | 套Set | 1 | 亘易隆GREENLONG |

3 | 挤出螺杆Extrusion Screw | Φ45 | 件Pics | 1 | 亘易隆GREENLONG |

4 | 模头法兰Extrusion Nozzle | / | 件Pics | 1 | 亘易隆GREENLONG |

5 | 混炼电机Mixing Motor | 7.5KW | 台Set | 1 | 瑞德森/国茂REDSUN/GuoMao |

6 | 挤出电机Extrusion Motor | 2.2KW | 台Set | 1 | 瑞德森/国茂REDSUN/GuoMao |

7 | 切粒电机Dicing Motor | 0.75KW | 台Set | 1 | 瑞德森/国茂REDSUN/GuoMao |

8 | 密封罩Dust Cover | / | 件Pics | 1 | 亘易隆GREENLONG |

9 | 压料块Cover | / | 件Pics | 1 | 亘易隆GREENLONG |

10 | 料斗Feeder | / | 件Pics | 1 | 亘易隆GREENLONG |

产能明细

Detail for the production capacity

规格型号Model | 制料类型Material type | 产能(以不锈钢为例)Production capacity (Take stainless steel as an example) |

3L | 粉末+粘结剂 制新Product new Resin with Powder + Binder | 10-15KG/锅,周期约为60分钟(10-15 Kg/Pot, Cycle time is about 60 Min) |

水口料 制作回用料Recycle resin with Runner | 10-15KG/锅,周期约为30分钟(10-15 Kg/Pot, Cycle time is about 30 Min |

本机特点:Special good points

◆ 混炼造粒**组合,中间无需搬料

This machine integrates mixing and granulation into the whole, and no need to transfer the resin.

◆ 粒料长短可控、光滑度可控

we can adjust the resin's length and Smoothness.

◆ 智能温控,自动化程度高

Intelligent Temperature-controlled, High degree of automation

◆ 工作效率更高,性能更稳定

Higher efficiency and more stable performance

◆ 手动、自动可自由转换

Manual, automatic, freely convertible

◆ 伺服控制,易清理

Servo control, easy to clean

◆ 带粉尘回收和废气排放装置

Dust recovery and exhaust gas emission device

◆ 螺杆和料筒耐磨和抗腐蚀

The screw and barrel are wear resistant and resistant to corrosion

◆ 大推力螺杆设计,输送速度快

Large thrust screw design, fast delivery speed

◆ 体积小,占地面积少

Small size, small footprint

◆ 功耗小,耗电少

Low power consumption and less power consumption

混炼造粒完美组合,中间无需搬料

造粒是在原料细粉中加入一定量的塑化剂,制成粒度较粗,具有一定假颗粒级配,流动性好的团粒,以利于陶瓷胚料的成型。陶瓷粉料颗粒越细越轻,流动越差,同时粉料的比表面积大,占体积也大,因而成型时不能均匀的填充

混炼造粒一体机技术参数-3L的工作原理介绍?

混炼造粒一体机技术参数-3L的工作原理介绍? 混炼造粒一体机技术参数-3L的使用方法?

混炼造粒一体机技术参数-3L的使用方法? 混炼造粒一体机技术参数-3L多少钱一台?

混炼造粒一体机技术参数-3L多少钱一台? 混炼造粒一体机技术参数-3L使用的注意事项

混炼造粒一体机技术参数-3L使用的注意事项 混炼造粒一体机技术参数-3L的说明书有吗?

混炼造粒一体机技术参数-3L的说明书有吗? 混炼造粒一体机技术参数-3L的操作规程有吗?

混炼造粒一体机技术参数-3L的操作规程有吗? 混炼造粒一体机技术参数-3L的报价含票含运费吗?

混炼造粒一体机技术参数-3L的报价含票含运费吗? 混炼造粒一体机技术参数-3L有现货吗?

混炼造粒一体机技术参数-3L有现货吗? 混炼造粒一体机技术参数-3L包安装吗?

混炼造粒一体机技术参数-3L包安装吗? 手机版:

手机版: