耗气量(L/min):

装机功率:

处理量:

10-5000Kg/h分级效率:

高分级细度:

20-100目工作原理:

立式看了无动力气流分级机的用户又看了

留言询价

留言询价 电话询价

电话询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

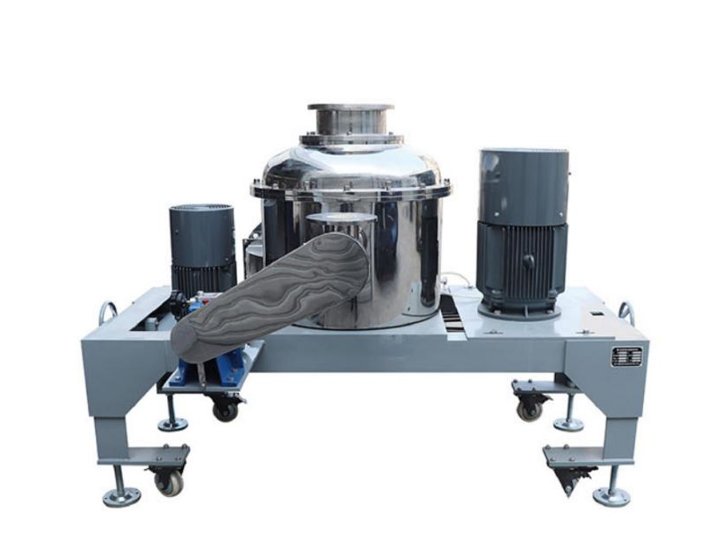

OMC系列·无动力气流分级机

OMC Series · Unpowered Air Flow Classifier

工作原理:

物料被定量加入到主机上方腔体内,在导流环的作用下被初步分散,在沿筒壁下落的过程中,又收到从下方补风口中进入的二次气流的进一步打散,该打散效果受到风量的影响,使用时可以通过调节分散环与筒壁的相对上下位置来调节,进而影响分选的精度,较细的颗粒会在上升气流的作用下向中心汇聚,并*终从*上方的出料口中离开,通过管道进入后道收尘设备(旋风分离器、布袋除尘器等),较粗的颗粒将继续沿筒壁而下,从*下端被卸出。

working principle:

The material is quantitatively added into the cavity above the main unit, and is initially dispersed under the action of the deflector ring. In the process of falling along the wall of the cylinder, it is further dispersed by the secondary air flow entering from the supplementary air inlet below. The scattering effect is affected by the air volume. When using it, it can be adjusted by adjusting the relative up and down positions of the dispersing ring and the cylinder wall, thereby affecting the accuracy of sorting. The finer particles will converge toward the center under the action of the upward airflow, and eventually leave from the top discharge port, it enters the downstream dust collection equipment (cyclone separator, bag dust collector, etc.) through the pipeline, and the coarser particles will continue to go down the cylinder wall and be discharged from the lowermost end.

设备特点:

主机不需要任何动件,因此能耗低,后期维护成本低廉,并且处理量相对较大。

通过调节分散环位置即可调节出料粒度,操作简单。

适用于为去除原料中的过细粉而产能要求又较高的物料分级。

1. The main unit does not need any moving parts, so the energy consumption is low, the maintenance cost in the later period is low, and the processing capacity is relatively large.

2. The particle size can be adjusted by adjusting the position of the dispersion ring, and the operation is simple.

3. It is suitable for the classification of materials with high production capacity requirements to remove the excessively fine powder in the raw materials.

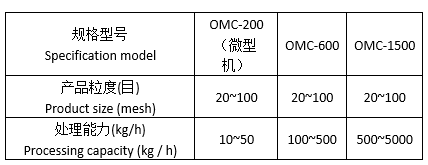

技术参数表(Technical Data Sheet):

注:具体配置及处理效果需根据物料性质与加工要求确认,可与我司工程师沟通或来料试验。

主机不需要任何动件,因此能耗低,后期维护成本低廉,并且处理量相对较大。

在半导体、光电材料及医药等高精度尖端领域,原材料的“无污染”纯净度是推动技术进步,确保产品安全、性能卓越的关键要素。特别是在半导体制造领域,杂质可以影响半导体的电导率,导致性能降低或者失效。在这些杂质

一直以来“铁”质材料是一种常见的耐磨材料,尤其像锰钢、白口铸铁、合金钢等是几种广泛应用的耐磨材料。但这些材料存在一定的弊端,例如奥氏体锰钢具有良好的韧性,但是加工较困难;普通白口铸铁和低合金白口铸铁有

超细粉碎技术是为适应现代技术要求而发展起来的一种新的粉碎技术,能把原材料加工成微米甚至纳米级的微粉,由于颗粒向微细化发展,导致物料表面积和孔隙率大幅度的增加,因此超微粉体具有独特的物理和化学性质,如良

冬天气温低,柴油和水都比较容易冻着,在启动机械时就比较困难,同时零件磨损和燃油消耗量显著增加,所以在入冬之前必须采取相应的保养措施,对破碎机做彻底的检查、保养,确保工程机械安全过冬。在冬季保养粉碎机(

无动力气流分级机的工作原理介绍?

无动力气流分级机的工作原理介绍? 无动力气流分级机的使用方法?

无动力气流分级机的使用方法? 无动力气流分级机多少钱一台?

无动力气流分级机多少钱一台? 无动力气流分级机使用的注意事项

无动力气流分级机使用的注意事项 无动力气流分级机的说明书有吗?

无动力气流分级机的说明书有吗? 无动力气流分级机的操作规程有吗?

无动力气流分级机的操作规程有吗? 无动力气流分级机的报价含票含运费吗?

无动力气流分级机的报价含票含运费吗? 无动力气流分级机有现货吗?

无动力气流分级机有现货吗? 无动力气流分级机包安装吗?

无动力气流分级机包安装吗? 手机版:

手机版: