看了IH型不锈钢化工泵的用户又看了

留言询价

留言询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

|

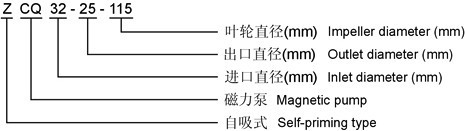

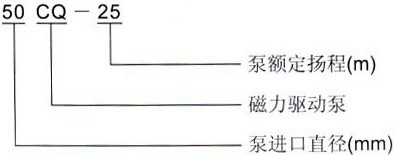

一、不锈钢化工泵的结构特点:泵盖通过止口固定在中间支架上,然后通过泵体与中间支架止口的联接把泵盖夹紧在中间,泵体是轴向吸入,径向排出,脚支承式,可直接固定在底座上。悬架部件通过止口固定固定在中间支架上,并用悬架支架支撑在底座上。为拆卸方便,设计了加长联轴器,检修时可以不拆卸进出口联接管路,泵体和电动机。只需拆下联轴器的中间联接件,即可退出转子部件进行检修。这是国际上通用的一种结构形式。 二、不锈钢化工泵的旋转方向:泵通过加长联轴器由电动机直接驱动,从电动机端看,按顺时针方向旋转。 三、不锈钢化工泵的轴封型式:填料密封:泵盖内设有填料函,采用软填料密封,填料函内可通入有一定压力的水,供密封冷却,润滑、清洗用。机械密封:单端面机械密封和双端面机械密封两种型式,密封腔内通入一定压力的水,冲洗磨擦两端面,同时起冷却作用。泵的密封型式采用填料密封或机械密封,由用户根据需要适用,同时根据需要允许采用适合于ISO3069规定的密封空腔尺寸和其他结构的轴封型式,如带波纹管的机械密封和付叶轮密封等等。IH型不锈钢化工泵输送介质温度为-20℃~105℃,需要时采用双端面密封冷却装置,可输送介质温度为20℃~+280℃。适用于化工、石油、冶金、电力、造纸、食品、制药、环保、废水处理和合成纤维等行业用于输送各种腐蚀的或不允许污染的类似于水的介质。四、IH型系列泵的性能范围:流量Q:6.3~400m3/h 扬程H:5~132m转速n:2900、1450r/min 配带功率:0.55~110KW进口直径:50~200mm **工作压力:1.6MpaIH型化工泵有29个基本型,其中22个双速(2900、1450r/min)经过A、B两种型式的叶轮直径切割变型后,达112个规格。五、结构图:1 泵体 2 叶轮 3 密封环 4 叶轮螺母 5 泵盖 6 密封部件 7 中间支架 8 轴 9 悬架部件六、型号意义:IH型不锈钢化工泵(性能参数): 型 号流 量扬程 (m)转速 (r/min)功率 (kW)效率 (%)必须汽 蚀余量 (NPSH)r(m)(m3³/h)(L/s)轴功率电机功率*50-32-1257.512.515.02.083.474.1723201829001.091.331.502.24351492.02.02.550-32-125A6.811.313.61.893.143.7818.816.414.70.871.011.161.54050472.02.02.550-32-1607.512.515.02.083.474.1734.532302.132.372.4533346502.02.02.550-32-160A6.811.313.61.893.143.7828.526.424.81.761.851.9133044482.02.02.550-32-2007.512.515.02.083.474.1751.850483.784.364.565.52839432.02.02.550-32-200A6.811.313.61.893.143.7842.74139.53.163.243.5742538412.02.02.550-32-2507.512.515.02.083.474.17828078.57.288.258.7911233336.52.02.02.550-32-250A711.7141.943.253.8971.97068.86.846.977.71112032342.02.02.550-32-250B6.611.013.21.833.063.6763.66260.95.716.196.647.53030332.02.02.565-50-1251525304.176.948.3321.32018.61.852.22.434762632.02.02.565-50-125A13.622.727.33.786.317.5817.616.515.41.481.671.913446159.92.02.02.565-50-1601525304.176.948.3334.232303.183.824.155.54457592.02.02.565-50-160A13.622.727.33.786.317.5828.426.524.82.562.933.2944156562.02.02.565-40-2001525304.176.948.3353.25047.65.306.557.2711415253.52.02.02.565-40-200A13.622.727.33.786.317.5843.94139.34.285.075.737.53850512.02.02.565-40-2501525304.176.948.3381.28078.49.7611.8412.8153446502.02.02.565-40-250A1423.4283.896.57.787174.868.68.7310.611.13153145472.02.02.565-40-250B13.22226.43.676.117.3362.861.853.07.298.428.45113144452.02.02.565-40-3151525304.176.948.33126.812512418.521.823.830283942.52.02.02.565-40-315A1423.4283.896.57.78111.2109.5108.818.1018.3622.12302538402.02.02.565-40-315B13.22226.43.676.117.3398.096.595.914.6915.6317.67222437392.02.02.580-65-1253050608.3313.916.723.22017.63.163.954.295.56069673.03.04.080-65-125A27.245.354.47.5612.5815.1219.116.514.52.483.043.3645767643.03.04.080-65-1603050608.3313.916.7363228.45.166.57.147.55767652.02.33.380-65-160A27.245.354.47.5612.5815.1229.726.423.44.085.025.397.55465622.02.33.380-50-2003050608.3313.916.755.25045.28.510.811.9155363622.02.53.280-50-200A27.245.354.47.5612.5815.1245.44137.26.738.299.35115061592.02.53.280-50-2503050608.3313.916.784807516.020.622.7304353542.52.52.580-50-250A28.1446.956.287.8213.0315.6373.5570.567.413.216.117.82242.75658.032.52.53.080-50-250B26.44452.87.3312.2214.6764.862.26011.413.815.018.540.865457.522.52.53.080-50-3153050608.3313.916.712812512333.134.138.0453850532.52.53.080-50-315A28.1446.956.287.8213.0315.63113.4110107.421.528.130.03740.450552.02.02.580-50-315B26.44452.87.3312.2214.67100.5979517.024.225.03043.54854.62.02.02.5100-80-1256010012016.727.833.323.720.016.35.967.477.721165736934.24.8100-80-125A5591.8109.015.325.530.519.416.813.74.685.906.127.562716734.24.8100-80-1606010012016.727.833.337322810.111.912.5156073733.84.35.0100-80-160A54.691109.215.1725.2830.3430.626.523.27.989.259.8515577170.43.84.35.0100-65-2006010012016.727.833.356504414.518.920.3226372713.43.95.2100-65-200A54.691109.215.1725.2830.3446.541.536.611.514.716.018.560.170683.43.95.2100-65-2506010012016.727.833.388807425.232.036.1375768673.03.64.5100-65-250A56.1193.5112.215.5825.9731.16777064.721.827.430.9375465643.03.64.5100-65-250B52.787.8105.414.6424.3929.2867.961.757.018.323.126.03053.36462.93.03.64.5100-65-3156010012016.727.833.313212511944.954.960.8754862642.83.24.2100-65-315A56.1193.5112.215.5825.9731.16115.510910439.245.552.1554561612.83.24.2100-65-315B52.788105.414.6424.4429.28102979233.338.744.0554460602.83.24.2125-100-20012020024033.355.666.761504129.335.438.3456877704.55.05.8125-100-200A109.1182218.230.350.5660.650.541.43423.127.430.13764.97567.14.55.05.8125-100-25012020024033.355.666.790807347.458.164.5756275743.74.55.5125-100-250A112186.522431.151.862.27869.563.540.348.3554.5755973713.74.55.5125-100-250B105.5175.5211.029.348.7558.669.061.55634.241.446.055587169.93.74.55.5125-100-31512020024033.355.666.7132.512512065.394.610311052.672754.04.55.0 |

暂无数据!

ZCQ型自吸式磁力泵结构图及安装尺寸点击次数:1432 发布时间:2013-3-28 23:28:00【ZCQ型自吸式磁力泵】产品简介:ZCQ型自吸式磁力泵是根据众用户的要求,在CQ型磁力泵的基础上吸

CQ型磁力驱动泵安装尺寸图点击次数:1309 发布时间:2013-3-28 23:30:59【CQ型磁力驱动泵】产品简介:CQ型不锈钢磁力驱动泵(简称磁力泵)是将永磁联轴器的工作原理用于离心泵的新产品

稳压泵的流量如何确定点击次数:867 发布时间:2012-9-18 10:45:38我国现行规范《高层民用建筑设计防火规范》(GBJ50045-95)(以下简称《高规》)对增压设施(其中包括稳压泵)有

ZW自吸排污泵使用范围及工作原理点击次数:1043 发布时间:2012-3-8 19:13:47 ZW自吸排污泵广泛用于工厂商业严重污染废水的排放、主宅区的污水排污站、城市污水处理厂派水系统

如何选择磁力泵材料点击次数:1024 发布时间:2012-3-8 20:15:23磁力泵磁性材料的选用各国基本熟悉同一,NdFeB材料工作温度低于150℃,SmCo材料工作温度低于250℃,对于微型泵

非金属泵的性能特点点击次数:998 发布时间:2012-3-10 9:52:04非金属泵的结构、材料与金属泵差异甚大,因此,其性能特点也有较大区别。 (1)泵体耐压性低 由于非

IH型不锈钢化工泵的工作原理介绍?

IH型不锈钢化工泵的工作原理介绍? IH型不锈钢化工泵的使用方法?

IH型不锈钢化工泵的使用方法? IH型不锈钢化工泵多少钱一台?

IH型不锈钢化工泵多少钱一台? IH型不锈钢化工泵使用的注意事项

IH型不锈钢化工泵使用的注意事项 IH型不锈钢化工泵的说明书有吗?

IH型不锈钢化工泵的说明书有吗? IH型不锈钢化工泵的操作规程有吗?

IH型不锈钢化工泵的操作规程有吗? IH型不锈钢化工泵的报价含票含运费吗?

IH型不锈钢化工泵的报价含票含运费吗? IH型不锈钢化工泵有现货吗?

IH型不锈钢化工泵有现货吗? IH型不锈钢化工泵包安装吗?

IH型不锈钢化工泵包安装吗? 手机版:

手机版: