看了双通道电池浆料磁网过滤的用户又看了

留言询价

留言询价 电话询价

电话询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

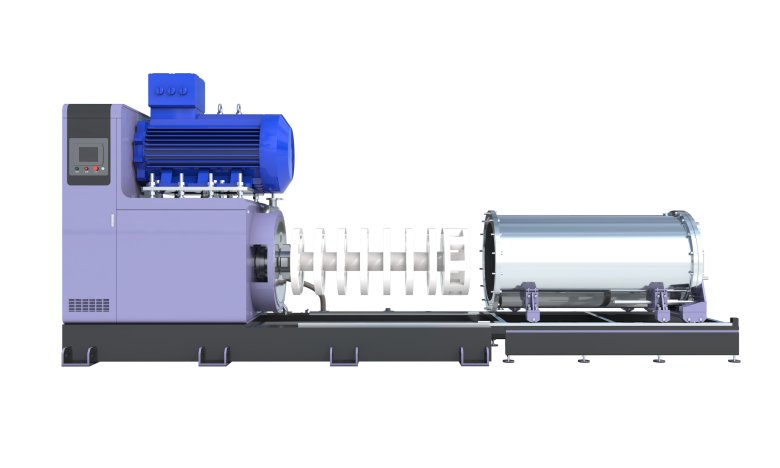

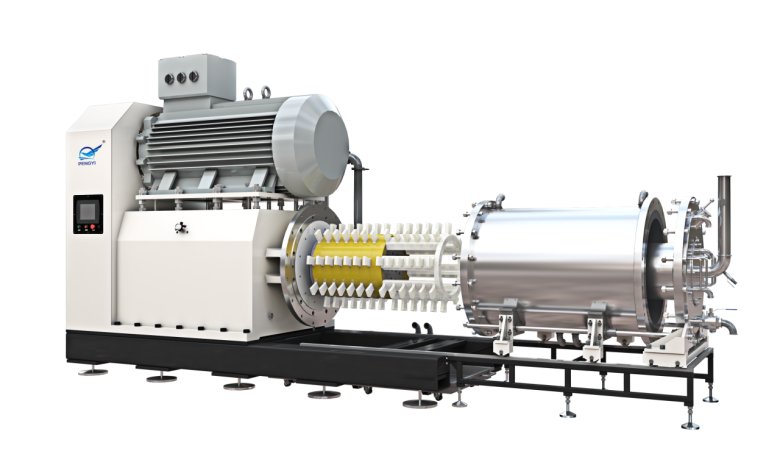

双通道电池浆料磁网过滤

Dual-channel Battery Slurry Magnetic Filtering

一、设备功能特点: Main Features:

1.双过滤通道配置(1套常用、1套备用),适用于浆料连续供料;两组过滤通道可自由切换;

Dual Filtering Channels: one for using, the other one for spare, which can ensure continuous supply of battery slurry. And the two channels can be switched freely.

2. 用于浆料从中转罐到涂布机输送及液面控制(有除铁、过滤杂质功能)。

It is also used for delivering the battery slurry from transferring tank to coating machine, controlling slurry level and filtering iron and impurities.

3.系统包含:This system includes

l 隔膜泵Diaphragm Pump

l 双通道磁铁过滤:磁棒,磁性强,高出同类产品约30%,超强寿命,10年磁力仅衰减1%。

Dual Channel Magnet Filtering: Our magnetic bar has about 30% stronger magnetic than the common one, whose lifetime is longer as its magnetic force decays only 1% for 10 years.

l 双通道网过滤:正极采用100-150目过滤网,负极采用100-150目过滤网,并联使用,单网过滤面积≥2000cm2.

Dual Channel Filtering: The positive electrode adopts 100-150 mesh filtering, the negative electrode adopts 100-150 mesh filtering, and it is used in parallel. Each mesh filter area is ≥2000cm2.

l 中转罐连接的管路,能实现自动化控制。

The pipeline connected to the transfer tank can be controlled automatically.

4. 双通道过滤器与控制器一体

Dual channel filtering and controller are integrated

5. 出料方式:采用底部出料工艺,无积料,杜绝材料浪费

Discharging way: The slurry is discharged from the bottom with no material accumulation and no material waste.

二、设备基本配置:Configuration

隔膜泵 | 1台,规格2.4m3/H,扬程:50米,吸程:7米,口径:1寸 |

磁铁及网状过滤器 | 磁棒规格:Φ25×200,磁性强度:12000GS/根,磁棒7根/单通; 网过滤器2个(双通道,带有压力检测,并能超压自动报警) |

管路、底座及管道连接 | |

控制系统 | 液位传感器1个、控制箱1个、二联体1个,流量控制器一套; |

推车 | 推车1个、隔膜泵和过滤器固定在车上,可任意移动,也可以固定。 |

Diaphragm Pump | 1Set,Specification: 2.4m3/H,Head of Delivery:50米,Head:7米,Size:1寸 |

Magnet and Gauze Filter | Specification of Magnet Bar:Φ25×200,Magnetic Strength:12000GS/Piece,7 Magnet Bars Per Channel; 2 Gauze Filters(Double Channels with pressure testing over-pressure automatic alarm) |

Pipe, Base and Pipe Connection | The base is equipped with 4 casters, 1 anti-corrosion soft steel wires and DN16. There is no dead angle on outlet pipe, pipe and equipment interface. |

Controlling System | 1 Liquid Level Sensor, 1 Control Cabinet, 1 Two Couplet, 1 Set Flow Controller; |

Cart | One Cart fixed with diaphragm pumps and filters. |

.双过滤通道配置(1套常用、1套备用),适用于浆料连续供料;两组过滤通道可自由切换;

Dual Filtering Channels: one for using, the other one for spare, which can ensure continuous supply of battery slurry. And the two channels can be switched freely.

2. 用于浆料从中转罐到涂布机输送及液面控制(有除铁、过滤杂质功能)。

It is also used for delivering the battery slurry from transferring tank to coating machine, controlling slurry level and filtering iron and impurities.

3.系统包含:This system includes

l 隔膜泵Diaphragm Pump

l 双通道磁铁过滤:磁棒,磁性强,高出同类产品约30%,超强寿命,10年磁力仅衰减1%。

Dual Channel Magnet Filtering: Our magnetic bar has about 30% stronger magnetic than the common one, whose lifetime is longer as its magnetic force decays only 1% for 10 years.

l 双通道网过滤:正极采用100-150目过滤网,负极采用100-150目过滤网,并联使用,单网过滤面积≥2000cm2.

Dual Channel Filtering: The positive electrode adopts 100-150 mesh filtering, the negative electrode adopts 100-150 mesh filtering, and it is used in parallel. Each mesh filter area is ≥2000cm2.

l 中转罐连接的管路,能实现自动化控制。

The pipeline connected to the transfer tank can be controlled automatically.

4. 双通道过滤器与控制器一体

Dual channel filtering and controller are integrated

5. 出料方式:采用底部出料工艺,无积料,杜绝材料浪费

Discharging way: The slurry is discharged from the bottom with no material accumulation and no material waste.

随着《提振消费专项行动方案》的出台,家居家装领域被明确列为提振消费的重点方向,涂料行业作为基础建材产业,迎来政策与市场的双重利好。方案提出“推动家装等大宗耐用消费品绿色化、智能化升级”,并强调通过超长

在工业设备领域,一台机器若能稳定运行十年以上,无疑是对其性能和耐用的最佳证明。近日,我们收到来自俄罗斯客户的反馈:其2010年采购的鹏翼智能砂磨机至今已连续使用15年,依然保持高效运转,成为当地生产线

3月19日,全球涂料行业瞩目的第29届国际油漆和涂料展览会Interlakokraska在万众期待中盛大开幕。Interlakokraska全面反映了油漆和涂料行业的发展动态,展品范围覆盖行业全链条,

随着材料科学的不断发展,许多行业需要越来越细的产品作为原材料,对于非金属矿加工来说,其核心技术是粉体技术,要想规模化生产细粒级产品,砂磨机是一个不错的选择。自上世纪80年代以来,在涂料、食品及医药等诸

水性漆以水为溶剂,凭借低VOC排放、无毒环保的特性,成为涂料行业转型升级的核心方向,广泛应用于建筑、汽车、家具、工业防腐等领域,市场规模年均增速超15%。然而,行业快速发展的背后仍面临多重痛点:生产效

无机颜料行业概述无机颜料行业是涂料、塑料、油墨、造纸等多个关键行业的基础支撑,其产品广泛应用于日常生活和工业生产的各个领域。无机颜料不仅赋予产品丰富的色彩,还提供遮盖力、耐候性、耐化学性等重要性能。随

双通道电池浆料磁网过滤的工作原理介绍?

双通道电池浆料磁网过滤的工作原理介绍? 双通道电池浆料磁网过滤的使用方法?

双通道电池浆料磁网过滤的使用方法? 双通道电池浆料磁网过滤多少钱一台?

双通道电池浆料磁网过滤多少钱一台? 双通道电池浆料磁网过滤使用的注意事项

双通道电池浆料磁网过滤使用的注意事项 双通道电池浆料磁网过滤的说明书有吗?

双通道电池浆料磁网过滤的说明书有吗? 双通道电池浆料磁网过滤的操作规程有吗?

双通道电池浆料磁网过滤的操作规程有吗? 双通道电池浆料磁网过滤的报价含票含运费吗?

双通道电池浆料磁网过滤的报价含票含运费吗? 双通道电池浆料磁网过滤有现货吗?

双通道电池浆料磁网过滤有现货吗? 双通道电池浆料磁网过滤包安装吗?

双通道电池浆料磁网过滤包安装吗? 手机版:

手机版: