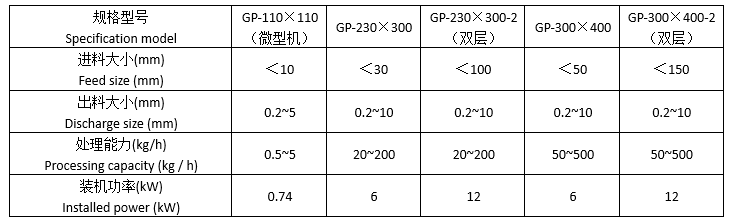

粉碎程度:

细粉碎单位能耗:

低产量:

0.5-500Kg/h装机功率(kw):

0.74-12成品细度:

0.2-10mm入料粒度(mm):

<150工作原理:

辊压碾磨 留言询价

留言询价 电话询价

电话询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

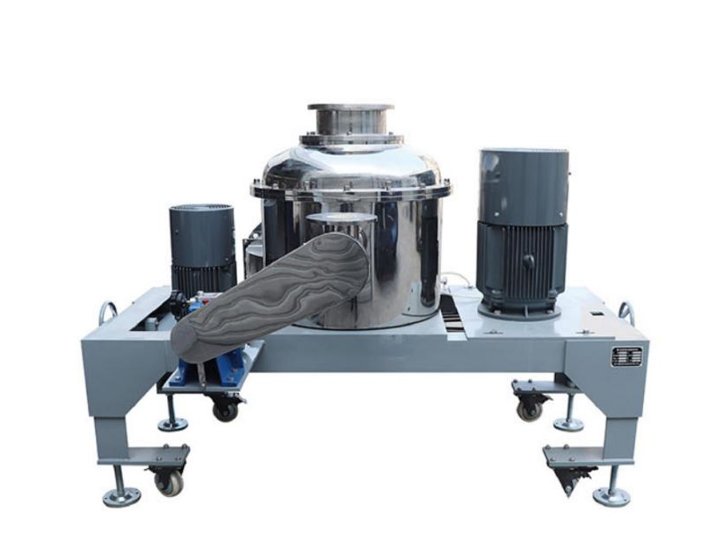

GP系列·全陶瓷无污染辊式破碎机

GP series · All ceramics contamination-free roller crusher

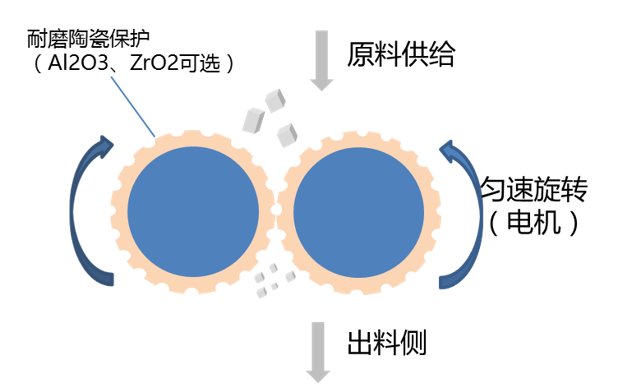

工作原理:

小块状或颗粒状物料被投入破碎腔后,受到来自两辊相向转动产生的挤压和咬合,从而被破碎通过两辊之间的间隙出料。

working principle:

After being put into the crushing cavity, small or granular materials are crushed and bitten by the opposite rotation of the two rollers, so that they are crushed and discharged through the gap between the two rollers.

设备特点:

适用于脆性物料的粗破碎,应用于锂电池材料、电子材料、高纯化工材料、高新陶瓷材料领域。

冲击磨损部位全部耐磨陶瓷防护,从而满足多数高新材料避免金属杂质污染要求,关键部位包括两支瓷辊等。

可根据物料性质和客户要求,对瓷辊进行抽槽处理以增加咬合力,也可以对接为双层对辊从而接受较为大块的原料破碎;可提供全密闭破碎形式,避免粉尘外泄且可通入惰性气体保护破碎。

1. It is suitable for the coarse crushing of brittle materials, and is used in the fields of lithium battery materials, electronic materials, high-purity engineering materials, and high-tech ceramic materials.

2. All impact wear parts are protected by wear-resistant ceramics to meet the requirements of most high-tech materials to avoid the contamination of metal impurities. The key parts include two ceramic rollers.

3. According to the material properties and customer requirements, the ceramic roller can be grooved to increase the bite force, or it can be combined as a double-layer roller to accept the crushing of larger pieces of raw materials; it can provide a fully enclosed crushing form to avoid dust leakage and can pass inert gas to protect the crushing.

技术参数表(Technical Data Sheet):

注:具体配置及处理效果需根据物料性质与加工要求确认,可与我司工程师沟通或来料试验。

Note: The specific configuration and processing effect need to be confirmed according to the material properties and processing requirements, and you can communicate with our engineers or come to do materials processing test first.

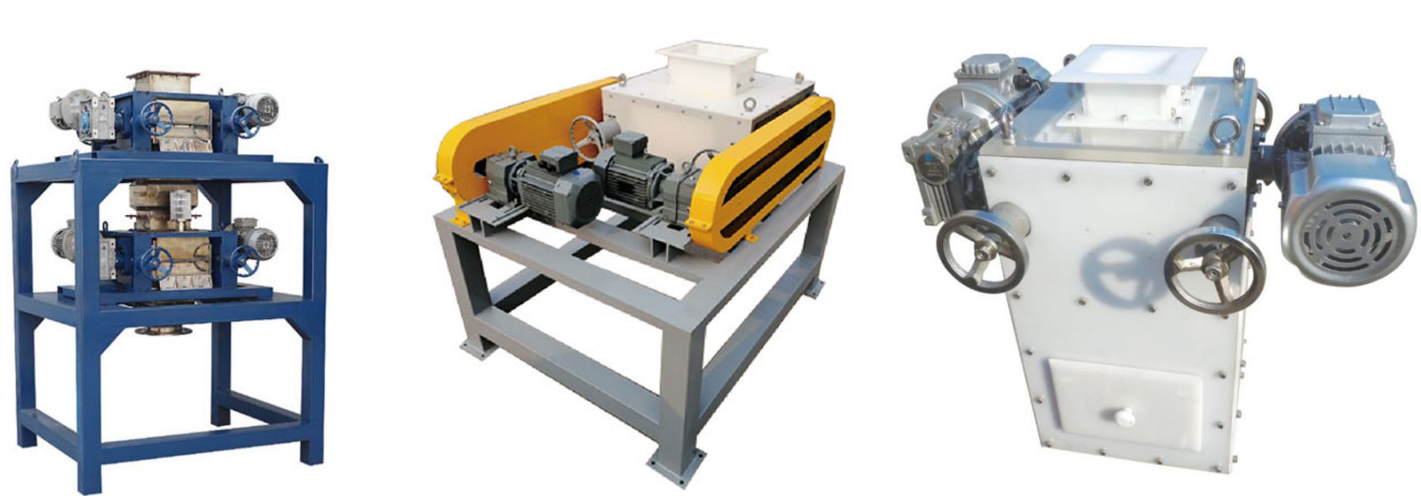

实物图片(Physical picture):

GP-230*300(中型机) GP-230*300(皮带式) 微型机

GP-230*300(中型机)(Medium model) GP-230*300(中型机)(Belt type) Micromodel

相关**: 全陶瓷齿轮辊式粉碎机(实用新型ZL 201621158532.9)

全陶瓷齿轮辊式粉碎机(发明ZL 201610934322.2)

一种带均匀导料功能的全陶瓷辊式破碎机(实用新型 ZL 201821570126.2)

暂无数据!

在半导体、光电材料及医药等高精度尖端领域,原材料的“无污染”纯净度是推动技术进步,确保产品安全、性能卓越的关键要素。特别是在半导体制造领域,杂质可以影响半导体的电导率,导致性能降低或者失效。在这些杂质

一直以来“铁”质材料是一种常见的耐磨材料,尤其像锰钢、白口铸铁、合金钢等是几种广泛应用的耐磨材料。但这些材料存在一定的弊端,例如奥氏体锰钢具有良好的韧性,但是加工较困难;普通白口铸铁和低合金白口铸铁有

超细粉碎技术是为适应现代技术要求而发展起来的一种新的粉碎技术,能把原材料加工成微米甚至纳米级的微粉,由于颗粒向微细化发展,导致物料表面积和孔隙率大幅度的增加,因此超微粉体具有独特的物理和化学性质,如良

冬天气温低,柴油和水都比较容易冻着,在启动机械时就比较困难,同时零件磨损和燃油消耗量显著增加,所以在入冬之前必须采取相应的保养措施,对破碎机做彻底的检查、保养,确保工程机械安全过冬。在冬季保养粉碎机(

全陶瓷无污染辊式破碎机的工作原理介绍?

全陶瓷无污染辊式破碎机的工作原理介绍? 全陶瓷无污染辊式破碎机的使用方法?

全陶瓷无污染辊式破碎机的使用方法? 全陶瓷无污染辊式破碎机多少钱一台?

全陶瓷无污染辊式破碎机多少钱一台? 全陶瓷无污染辊式破碎机使用的注意事项

全陶瓷无污染辊式破碎机使用的注意事项 全陶瓷无污染辊式破碎机的说明书有吗?

全陶瓷无污染辊式破碎机的说明书有吗? 全陶瓷无污染辊式破碎机的操作规程有吗?

全陶瓷无污染辊式破碎机的操作规程有吗? 全陶瓷无污染辊式破碎机的报价含票含运费吗?

全陶瓷无污染辊式破碎机的报价含票含运费吗? 全陶瓷无污染辊式破碎机有现货吗?

全陶瓷无污染辊式破碎机有现货吗? 全陶瓷无污染辊式破碎机包安装吗?

全陶瓷无污染辊式破碎机包安装吗? 手机版:

手机版: