认 证:工商信息已核实

访问量:130364

概述 Descriptions

ZLPG系列中药浸膏专用喷雾干燥机,是一款专门用来解决植物萃取液的干燥装置,干燥后的物料颜色好、不变质,提高了工厂的经济效益;它采用全封闭形式,进风配有三级净化装置,过滤加热后的干燥空气可达十万级甚至更高要求。筒体与顶部装有冷壁装置,使壁温<80℃,经该机干燥后的产品,不会出现焦化变质现象;干燥塔内装有气刷扫塔装置,收粉率可达99%以上,且不会产生混药和粘壁现象;采用CIP在线清洗装置,使之能适用于多品种生产要求;尾气采用湿式水膜除尘,使粉尘无外泄,符合环保要求;系统采用PLC触摸屏模糊控制,并采用除湿制冷的干空气密闭输送成品至包装储料仓。

ZLPG traditional Chinese medicine extract spray dryer is a specialized for plant solution drying, drying product with good color, does not degenerate ,It improve the economy of the plant; it is fully enclosed form equipped with three grade purification devices, filtered dry air up to one hundred thousand or even higher grade. Cylinder and the top installed cold wall device, so that the wall temperature less than 80 ℃, the product will not appear coking deterioration phenomenon; drying tower equipped with air cleaning device, the collection rate up to 99% , also does not produce mixing and sticky wall phenomenon; equipped with CIP-line cleaning device, it can be applied to more varieties of production requirements; exhaust wet scrubber make dust without leakage, in line with environmental requirements; system using PLC touch screen, and the use of dehumidification of dry air sealed delivery of finished products to the packaging storage silo.

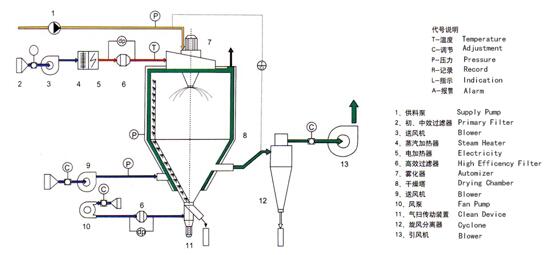

设备原理Equipment principle

空气通过加热器加热后,经送风机进入干燥塔顶部的热风分配器,通过热风分配器后,热空气均匀的进入干燥塔内,并呈螺旋状运动。料泵同时将料液送至干燥塔顶部的离心喷雾器,料液被喷成极小的雾状液滴。使料液和热空气接触的表面积大大增加,水份迅速蒸发,在极短时间内干燥为干品。干品由旋风分离器与湿空气分离,经旋风分离器底部的集料旋蜗室由干燥的空气送至小旋风分离器分离,并收集在收料筒,尾气经引风机排出。

干燥机的热风系统、吹扫系统、风送系统均配有初效、中效、亚高效等过滤器,凡进入干燥系统的风都经过滤处理。凡与物料接触部位均采用不锈钢制作,符合GMP要求。

Through the heater, hot air enter into the top of the drying tower hot air distributor via fan, through the hot air distributor, the hot air into the drying Chamber evenly, and spiral movement. The feed pump also sends the feed to a centrifugal sprayer at the top of the drying tower, where the liquid is sprayed into very small droplets of mist. So that the liquid material and hot air contact surface area greatly increased, the rapid evaporation of water in a very short period of time for dry goods. The dry product is separated from the wet air by the cyclone separator and sent to the small cyclone separator by the dry air from the bottom of the cyclone separator and collected in the collector. The exhaust gas is discharged by the blower.

Hot air system, purge system, wind delivery system are equipped with primary effect, high efficient and other filters, the air is filtered before enter into the drying Chamber. Stainless steel is applied in air contact parts in line with GMP requirements.

特点 Features

1. 塔体具有冷风夹套;

The tower body has a cold wind jacket;

2. 塔体上装有自动振打装置;

Chamber equipped with the automatic vibration device;

3. 塔体、管路配有快开清洗孔及排污孔;

Chamber and pipeline is equipped with fast-opening cleaning holes and sewage holes;

4. 可以配自动控制恒温加料罐;

Optional automatic temperature control feeding tank;

5. 可以配手工高压洗塔随机附件;

Optional manual high-pressure washing tower accessories;

6. 与物料接触的部分采用不锈钢材料制作;(或全不锈钢制造);

Stainless steel materials used in materials contact parts;

7. 物料收集采用旋风除尘器和湿式除尘器;

Dust collection system with cyclone and Scrubber

8. 进风温度实现自动控制及连续装置。

Intake air temperature achieves automatic control device.

9.可以配气扫装置。

Optional air clean device.

工艺流程图 Sketch of Flow Chart

- 推荐产品

- 供应产品

- 产品分类