认 证:工商信息已核实

访问量:18333

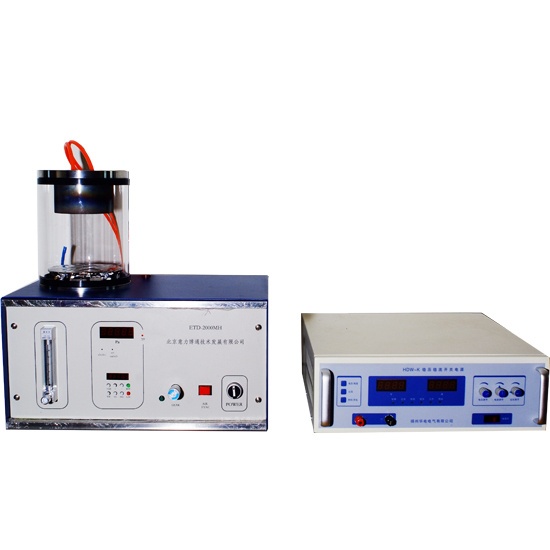

ETD-2000MH型磁控等离子溅射仪。

磁控溅射的工作原理是指电子在电场E的作用下,在飞向基片过程中与氩原子发生碰撞,使其电离产生出Ar正离子和新的电子;新电子飞向基片,Ar离子在电场作用下加速飞向阴极靶,并以高能量轰击靶表面,使靶材发生溅射。

在溅射粒子中,中性的靶原子或分子沉积在基片上形成薄膜,而产生的二次电子会受到电场和磁场作用,产生E(电场)×B(磁场)所指的方向漂移,简称E×B漂移,其运动轨迹近似于 磁控溅射 磁控溅射 一条摆线。若为环形磁场,则电子就以近似摆线形式在靶表面做圆周运动,它们的运动路径不仅很长,而且被束缚在靠近靶表面的等离子体区域内,并且在该区域中电离出大量的Ar 来轰击靶材,从而实现了高的沉积速率。随着碰撞次数的增加,二次电子的能量消耗殆尽,逐渐远离靶表面,并在电场E的作用下*终沉积在基片上。由于该电子的能量很低,传递给基片的能量很小,致使基片温升较低。

磁控溅射是入射粒子和靶的碰撞过程。入射粒子在靶中经历复杂的散射过程,和靶原子碰撞,把部分动量传给靶原子,此靶原子又和其他靶原子碰撞,形成级联过程。在这种级联过程中某些表面附近的靶原子获得向外运动的足够动量,离开靶被溅射出来。

配有高位定性的飞跃真空泵

ETD-2000MH magnetron plasma sputtering instrument.

The principle of magnetron sputtering is that the electrons collide with the argon atom in the process of flying to the substrate under the action of the electric field E, and make the ionization produce Ar positive ions and new electrons; the new electrons fly to the substrate, the Ar ion accelerates to the cathode target under the action of the electric field, and bombards the target surface with high energy to make the target sputtering.

In the sputtering particles, the neutral target atoms or molecules are deposited on the substrate to form a film, and the two electrons produced are affected by the electric field and the magnetic field. The direction drift of the E (electric field) * B (magnetic field), referred to as E x B drift, is similar to the magnetron sputtering of a cycloid. If a circular magnetic field is used, the electrons are circumferential on the surface of the target in the form of an approximate cycloid. Their motion path is not only long, but also bound to the plasma area near the target surface, and a large number of Ar are ionized in the region to bombard the target, thus achieving high deposition rate. As the number of collisions increases, the energy of the two electrons is depleted away and gradually away from the target surface, and finally deposited on the substrate under the action of electric field E. Because the energy of the electron is very low, the energy transferred to the substrate is very small, causing the substrate temperature rise to be low.

Magnetron sputtering is a collision process between incident particles and targets. The incident particles experience complex scattering process in the target, and collide with the target atoms, and transfer partial momentum to the target atom. The target atom collide with other target atoms and forms a cascade process. In this cascade process, the target atoms near some surfaces get enough momentum to move outward and sputter out of the target.

Vacuum pump equipped with high quality

| 配套泵 | 溅射靶材 | 溅射电流 | 极限真空度 | 样品仓尺寸 | 样品台尺寸 | 工作电压 |

| 涡轮分子泵(抽速为80L/S),两升飞跃真空泵 | 标配靶材为金靶,厚度为60mm*0.1mm。也可根据实际情况配备银靶、铂靶等。 | 电流0-500A | 5*10PA | 直径 180mm, 高200mm | 样品台尺寸直径80mm | 220V 50HZ |

需要镀膜的样品

| 电子束敏感的样品 | 非导电的样品 | 新材料 |

| 主要包括生物样品,塑料样品等。S EM中的电子束具有较高能量,在与样品的相互作用过程中,它以热的形式将部分能量传递给样品。如果样品是对电子束敏感的材料,那这种相互作用会破坏部分甚至整个样品结构。这种情况下,用一种非电子束敏感材料制备的表面镀层就可以起到保护层的作用,防止此类损伤; | 由于样品不导电,其表面带有“电子陷阱”,这种表面上的电子积累被称为“充电”。为了消除荷电效应,可在样品表面镀一层金属导电层,镀层作为一个导电通道,将充电电子从材料表面转移走,消除荷电效应。在扫描电镜成像时,溅射材料增加信噪比,从而获得更好的成像质量。 | 非导电材料实验电极制作观察导电特性 |

- 推荐产品

- 供应产品

- 产品分类